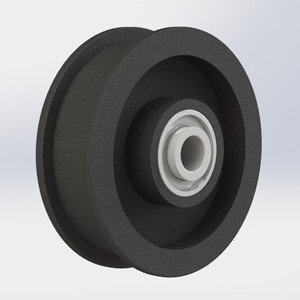

Product Description

Quick Details

Warranty:3 years

Applicable Industries:Manufacturing Plant, Retail, Construction works , Advertising Company

Customized support:OEM

Type:TIMING

Material:Aluminum ALLOY

Place of Origin:ZheJiang , China

Product name:Aluminium timing belt pulley

Color:Silver

Surface treatment:Anodic Oxidation/Mill finish

Size:Customized Sizes

Timing Pulley Type:Open Timing Pulley

Usage:Automatic mechanical equipment

Packing:Carton packing

Belt Width:10mm

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Toy, Agricultural Machinery, Car, Printer Cutter |

|---|---|

| Hardness: | Hardened Tooth Surface |

| Gear Position: | Internal Gear |

| Manufacturing Method: | Rolling Gear |

| Toothed Portion Shape: | Curved Gear |

| Material: | Aluminum |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

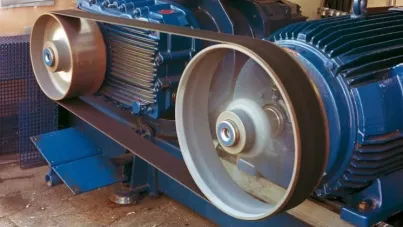

How do flat belt pulleys contribute to efficient power transmission?

Flat belt pulleys play a significant role in achieving efficient power transmission in various mechanical systems. Here’s a detailed explanation:

1. Large Contact Area:

Flat belt pulleys have a wide and flat contact surface with the belt. This large contact area allows for efficient power transfer by maximizing the frictional forces between the pulley and the belt. The increased contact area results in enhanced grip, reducing the likelihood of belt slippage and improving power transmission efficiency.

2. Flexibility and Tension:

The flexibility of flat belts enables them to conform to the shape of the pulleys and maintain contact along the entire width of the belt. This flexibility allows for effective power transmission around bends and over pulleys of different diameters. Additionally, proper tensioning of the belt ensures optimal contact and minimizes energy losses due to excessive belt sag or tightness.

3. Smooth Operation:

Flat belt pulleys, when properly aligned and balanced, offer smooth and vibration-free operation. This smooth operation reduces energy losses that may occur due to belt oscillation or excessive vibrations. It also helps to minimize noise and prolong the life of the belt and pulley components.

4. Adjustable Speed Ratios:

By using different-sized pulleys in a flat belt drive system, the speed ratio between the driving and driven pulleys can be adjusted. This allows for versatile power transmission, enabling the selection of the desired output speed based on the application requirements. The ability to adjust speed ratios contributes to efficient power utilization and the optimization of machinery performance.

5. Easy Maintenance and Replacement:

Flat belt pulleys are relatively easy to maintain and replace. Belt tension adjustments, pulley alignment checks, and periodic belt inspections can help ensure efficient power transmission. When replacement is necessary, flat belts are readily available and can be quickly installed, reducing downtime and improving overall system efficiency.

6. Cost-effectiveness:

Flat belt pulleys offer a cost-effective solution for power transmission compared to other types of drives. They are relatively simple in design, require minimal lubrication, and have lower initial costs compared to systems such as gear drives or chain drives. This cost-effectiveness makes flat belt pulleys a popular choice in a wide range of applications.

By maximizing the contact area, ensuring proper tension, providing smooth operation, allowing for adjustable speed ratios, and offering ease of maintenance, flat belt pulleys contribute to efficient power transmission. Their design characteristics and versatility make them suitable for various industrial and mechanical systems.

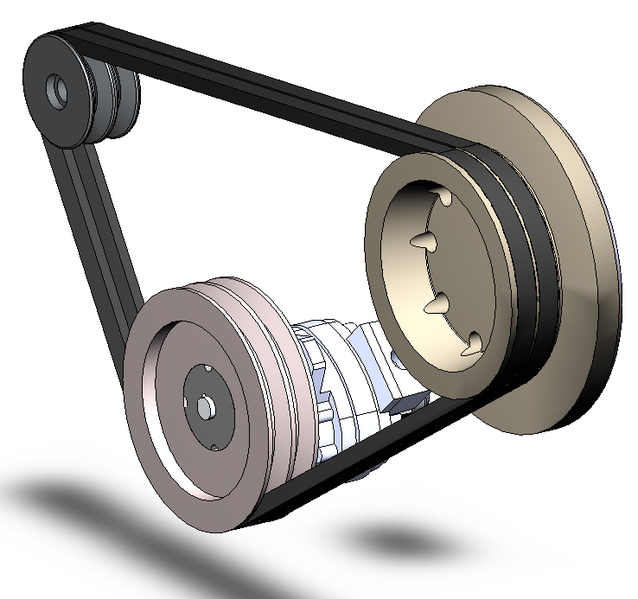

How does the design of a flat belt pulley affect its performance?

The design of a flat belt pulley plays a crucial role in determining its performance characteristics. Here’s a detailed explanation:

1. Groove Profile:

The groove profile of a flat belt pulley affects the grip and traction between the pulley and the belt. Different groove profiles, such as V-shaped, U-shaped, or flat, are used depending on the type of belt being used. The groove profile should be designed to optimize the belt’s contact area and prevent slippage, ensuring efficient power transmission.

2. Diameter and Width:

The diameter and width of the pulley directly impact its mechanical advantage and power transmission capabilities. Larger pulley diameters result in higher belt speeds and increased power transmission capacity, while wider pulleys provide better belt support and reduced belt stress.

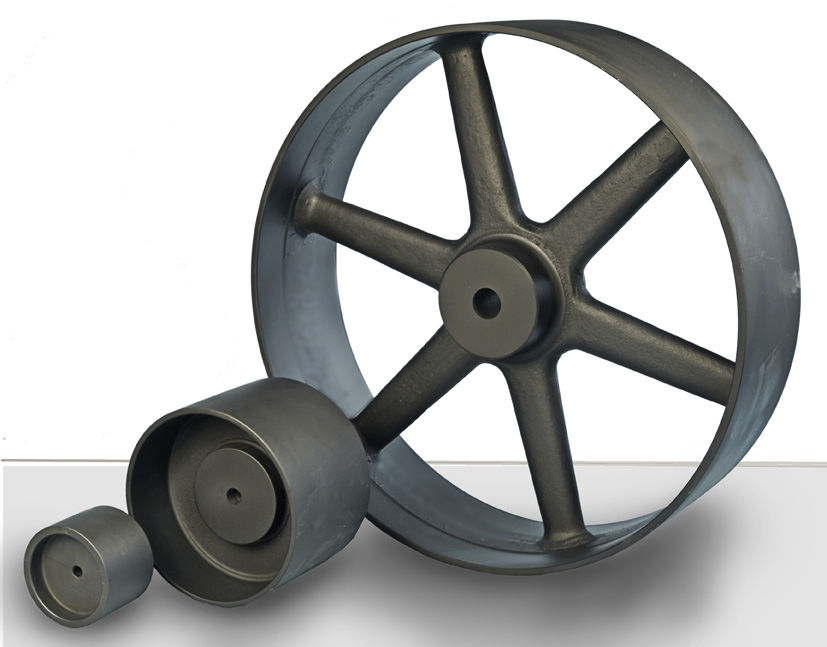

3. Material Selection:

The choice of material for the pulley affects its strength, durability, and resistance to wear and corrosion. Commonly used materials include steel, cast iron, aluminum, and plastics. The material selection should be based on factors such as the load capacity, operating environment, and desired lifespan of the pulley.

4. Balance and Alignment:

A well-designed flat belt pulley should be properly balanced and aligned to minimize vibration and ensure smooth operation. Imbalances or misalignment can result in increased noise, reduced efficiency, and premature wear of the pulley and belt.

5. Tensioning Mechanism:

The design of the tensioning mechanism, such as an idler pulley or tensioning screw, can impact the ease of belt tensioning and the ability to maintain proper belt tension over time. A well-designed tensioning mechanism ensures consistent and reliable power transmission by maintaining the optimal tension in the belt.

6. Flanges and Hub Configuration:

The presence of flanges or the configuration of the hub can affect the stability and alignment of the pulley. Flanges help to keep the belt contained within the pulley, preventing lateral movement and ensuring proper tracking. The hub configuration should provide a secure and accurate connection to the shaft, minimizing slippage or misalignment.

7. Surface Finish and Coating:

The surface finish and coating of the pulley can influence its friction characteristics, wear resistance, and corrosion protection. Smooth surface finishes and appropriate coatings can reduce friction, extend the life of the pulley and belt, and improve overall performance.

By carefully considering and optimizing these design factors, flat belt pulleys can be engineered to deliver efficient and reliable power transmission, minimize belt wear, and ensure long-lasting performance in various applications.

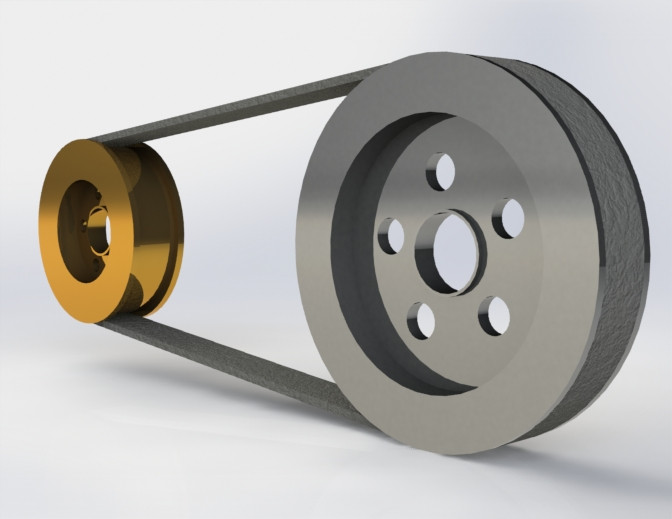

How do flat belt pulleys differ from other types of pulleys?

Flat belt pulleys have distinct characteristics that set them apart from other types of pulleys. Here’s a detailed explanation:

1. Belt Type:

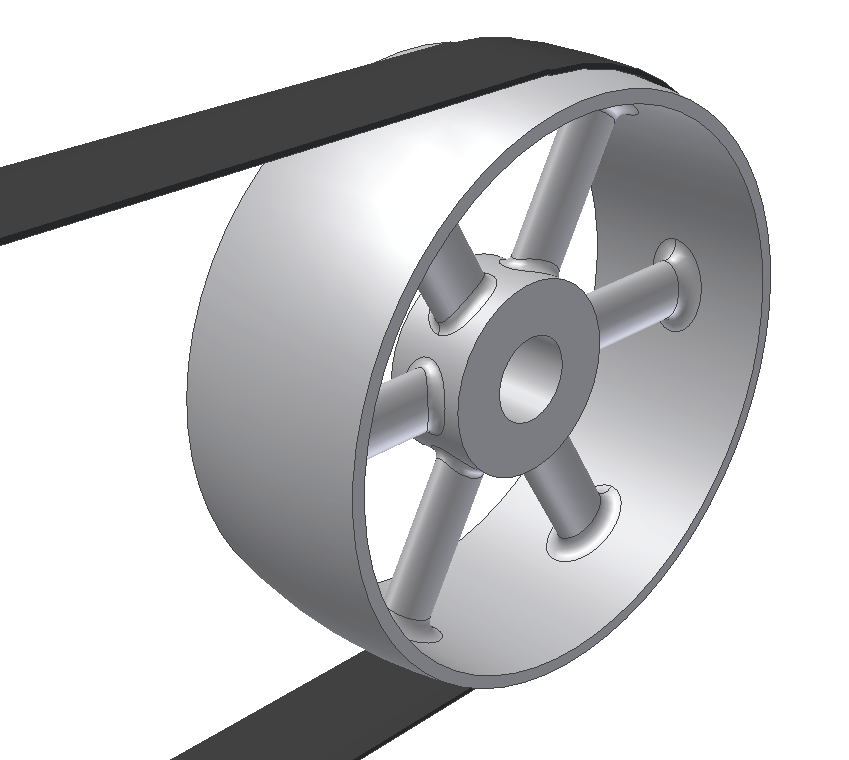

The major difference lies in the type of belt used. Flat belt pulleys are specifically designed to work with flat belts, which are flexible and have a rectangular cross-section. In contrast, other types of pulleys, such as V-belt pulleys or timing belt pulleys, are designed for different belt profiles, such as V-shaped belts or toothed belts.

2. Belt Engagement:

Flat belt pulleys engage with the belt differently compared to other pulley types. The flat belt wraps around the pulley’s flat or slightly concave surface and relies on friction to transmit power. Other pulley types, like V-belt pulleys, have grooves that match the shape of the belt, providing positive engagement by fitting into the belt’s grooves.

3. Power Transmission:

Each pulley type is optimized for specific power transmission requirements. Flat belt pulleys are often used for applications that require relatively low power and moderate speeds. They are suitable for machinery that needs flexibility and ease of installation, making them commonly used in older machinery and certain industrial applications. Other pulley types, like V-belt pulleys or timing belt pulleys, offer advantages for high-power transmission, increased efficiency, or precise timing in applications such as automotive engines or industrial machinery.

4. Pulley Design:

Flat belt pulleys have a simple design, typically consisting of a cylindrical or disk-shaped body with a flat or slightly concave surface. Other pulley types may have more complex designs to accommodate specific belt profiles. For example, V-belt pulleys have grooves that match the V-shaped belts, while timing belt pulleys have toothed profiles that match the teeth on the timing belts.

5. Speed and Torque Conversion:

The design and configuration of pulleys, including flat belt pulleys, allow for speed and torque conversion. By varying the sizes of the pulleys, the speed and torque can be adjusted to meet the requirements of the machinery. However, the specific mechanisms for speed and torque conversion may differ between pulley types. For example, V-belt pulleys rely on the varying diameters of the pulleys to achieve speed conversion, while timing belt pulleys use the toothed profiles to ensure precise timing and synchronization.

6. Belt Tension and Alignment:

The methods used to maintain belt tension and alignment can also differ between pulley types. Flat belt pulleys often rely on adjustable pulley positions or tensioning mechanisms to achieve proper tension and alignment. Other pulley types may incorporate features like automatic tensioners or specialized tensioning systems to maintain optimal belt performance.

In conclusion, flat belt pulleys differ from other types of pulleys in terms of the belt type, engagement method, power transmission capabilities, design, speed and torque conversion mechanisms, as well as belt tension and alignment methods. Understanding these differences is crucial for selecting the appropriate pulley type for a given application.

editor by CX

2024-05-17